My design says I can make a bowl from a board 48"

long x 5-3/4" wide x 3/4" thick. One end of this board has a big

unusable knothole in it, so I cut off that end of the board.

|

I ripped the two boards for my two compound-mitered segment

rings. The board for my top ring is 28" long x 2-1/2" wide. The board

for my bottom ring is 28" long x 3-1/8" wide.

|

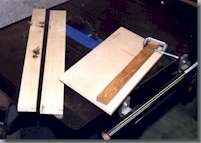

One of the boards is on my compound miter sled. I am cutting

the segments for a 12-sided, 70-degree incline angle, 10 " diameter

ring. Note the C-clamp stop.

|

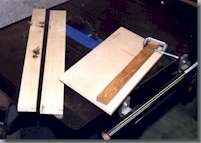

The 12 segments for one compound mitered ring are cut out. The

segments are cut consecutively from the board, just like it appears in

the photo. For illustration, I have reassembled the cut pieces into the

board.

|

I am now cutting out the flat mitered segments for the bowl's

central ring. The photo shows my flat miter sled. The sled fence is set

for a 12-sided ring.

|

All the bowl's segments are now cut. There are two compound

mitered rings for the bowl's top and bottom, two flat mitered rings for

the bowl central ring and lip ring, a base disk, and the leftover board

scrap. Not much usable scrap!

|

I am gluing together the segments for the central ring and the

lip ring. I use rubber bands to hold pairs of segments together. I

don't use anything to clamp pairs of glued pairs together, just

Titebond II glue. With a little glue between the segments, I rub the

segments together and carefully set the segments down on the sink

cutout.

|

This photo shows padauk veneer being glued to the compound

mitered segments. I rubber-band the segments to a plastic block to keep

the veneer flat while the glue dries. Glue doesn't stick to the plastic

block.

|

This is the veneer trimming operation. All of the compound

mitered segments have padauk veneer between them. Adding veneer doubles

or triples the time it takes to construct a bowl, but I think it's

worth it. Sometimes I'll glue several layers of veneer between segments.

|

Now I'm gluing the compound-mitered segments together to form

the bowl's top and bottom rings. The central ring and the lip ring are

finished.

|

To make the rings come out perfectly, I make half-circle

rings, then sand the butts flat. The two half-rings will fit together

perfectly using this method. I use a 12" disk sander for small rings

and a 6"x48" belt sander for big ones.

|

I use a faceplate with a thick wastewood block attached. The

new bowl's base disk and disks of padauk and blackwood are ready to be

glued to the faceplate.

|

This photo shows the clamping setup (using my drill press) for

the faceplate and base disk. Also shown is how I rubber-band the

half-ring to the sink cutout to keep the veneer flat while the glue

dries.

|

Here are the two completed compound mitered top and bottom

rings. The topmost ring will be the bowl's bottom ring. I pre-planned

the knot hole to be located on the top ring so it will be more visible.

I like wood to look like wood - knots are great!

|

I use a Wagner Safety Planer (from Woodcraft Supply) to

flatten the compound mitered rings. I have found this method to be the

safest of all the methods I've tried for flattening rings. It's also

very fast.

|

I usually flatten both sides of each compound mitered

ring with the safety planer.

|

This is the clamping setup for gluing the rings together. I

don't put much downward pressure on the compound mitered rings. The

veneered joints aren't strong until the next ring is glued on, rotated

by 1/2 segment..

|

I put the assembly from the previous photo in my lathe to

flatten the face (true it up) and turn the perimeter round. I use the

rounded ring perimeter to help keep the next glued-on rings

concentric.

|

Veneer is being glued to the trued up compound-mitered bottom

ring. I make the veneer pieces in 1/4 circle arcs to save wood waste.

|

The veneer ring is finished . Now the central ring is being

glued onto the assembly. This knot hole will be hidden by the

ornamental banding.

|

Veneer is being glued to the flattened compound-mitered upper

ring. Again, I use the drill press to keep the veneer flat while the

glue dries.

|

The compound-mitered top ring is now being glued to the

assembly.

|

The final veneer that goes between the compound-mitered top

ring and the lip ring is being glued into place.

|

The lip ring is being glued into place. The bowl assembly is

now complete.

|

The complete assembly is on the lathe. Now it's time to round

it out.

|

Another view of the same.

|

Still another view.

|

I have completely rounded the bowl. I round the outside, then

I round the inside. I cut extra material out of the inside to get my

desired thickness. I use gouges and skews on the outside. I generally

use a hollowing tool and several different kinds of scrapers on the

inside.

|

I have cut a shallow groove in the central ring and glued in

the veneer banding strip. I held the strip in place with rubber bands

while the glue dried.

|

The final lathing of the base disk is now complete. The

outside surface of the bowl has been lightly sanded, then burnished

with a Scotch-brite pad. The next step is to part the bowl off the

lathe by cutting through the waste block on the faceplate.

|